RECYCLING OF WASTE SILICONE POLYMERS

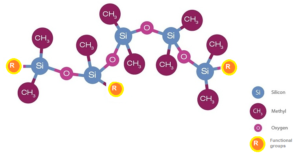

Dialkylpolysiloxanes also known as silicone, are man-made polymers that include any inert, synthetic compound made up of repeating units of siloxane, which is a chain of alternating silicon atoms and oxygen atoms, frequently combined with carbon or hydrogen or both.

They are occurring in many physical forms as low and high viscosity fluid, gel, gums, rubber, resins etc having variety of applications in industry as well as in our day to day life.

Various functionalities to the basic backbone chain of silicones impart different physical and chemical properties, as a result mostly adopted polymer in improving the quality of life by mankind.

Silicone, thus having various added advantage as far as applicability concern, poses high concerns due to its poor degradation rate naturally. This increases the risk of accumulation of waste silicone polymer all over the globe.

An approach to address the recycle of this waste silicone polymer with an environmental benign, non- hazardous, economical, safe way need to be reviewed.

Recycling of silicone polymer implies reuse of the waste polymer as polymer; broadly categories as

- recycling of industrial scrap and

- Post-consumer recycling

The former primarily involves recovering and reusing waste polymer resulting from processing operations. This has long been practiced by many industrial groups. It is simpler than the latter.

In post consumer recycling of polymers, they are particularly of mixed kind and they are collected and segregated by experienced people. The practice is motivated by economics.

Therefore, efficient recycling should give new opportunities for reintegration of discarded materials into the economic cycle, increase the added value of products out of recycled materials, create a sustainable solution to the polymer waste problem, and decrease dependence of businesses on oil-based raw materials and energy. The most common recycling methods are mechanical recycling, chemical recycling, and combustion.

Supreme Silicones, through its continuous R&D activities, achieved mastery over economic recycling of silicone polymers. Comminuted Silicones polymers are fed to reactor for chemical degradation in presence of catalyst to depolymerise the siloxane backbone. The cleavage of bonds take place as energy required for bond dissociation is supplied in the form of heat. The catalyst alters the rate of reaction and the process results in formation of silicon monomeric materials. Reactions can be fine tuned to get the desired low molecular weight polymers. Various functional silicone polymers and its copolymers can be synthesised using this technique.

Advantages :

Recycling minimizes pollution

All forms of pollution in the modern world emanate from industrial waste. Recycling of the industrial wastes such as plastics, cans, and chemicals go a long way towards considerably cutting back on levels of pollution because these waste products are reused rather than just being thrown away recklessly.

Protects the environment

The great benefit of recycling waste material is that it plays a big part in protecting Mother Nature in the most balanced way. While many trees are felled every day, recycled paper manufactured from specific trees is continually utilized to reduce deforestation. This classical example demonstrates that other natural resources can be recycled and made useful this way to conserve the environment.

Recycling minimizes global warming

It is perfectly true that recycling minimizes global warming and its grave impacts. During waste disposal, huge amounts of waste are combusted that lead to emission of vast greenhouse gases such as carbon dioxide, sulfur, and nitrogen, which contribute to climate change and global warming.

Recycling process involves minimal combustion and waste is transformed into reusable materials with zero or minimal harmful impact on the environment. The whole process of processing and manufacturing products from waste materials emits few greenhouse gases because the very waste recycling industries burn little fossil fuels.

Conserves natural resources

If the process of recycling used and old materials was not there, it means new products will be manufactured by extraction of fresh raw materials underneath the earth through the process of mining and extraction. Recycling is a surefire way of conserving existing raw materials and protecting them for future use. Taking steps to conserve natural resources like minerals, water and wood ensures sustainable and optimal use.

Recycling cuts down amount of waste in landfill sites

Recycling old and used materials into reusable products enormously reduces the possibility of choking of landfill sites. This is beneficial because it helps minimize land and water pollution since landfills contributes mightily to environmental degradation.

Recycling ensures sustainable use of resources

Recycling guarantees that existing resources will be used sensibly and sustainably. The recycling process alleviates the possibility of discriminate use of raw materials when they are obtainable in huge supply. Governments these days have stepped in to encourage recycling from lower levels, for instance, schools, small-sized organizations and also at global levels. This means that manufacturing industries can leave existing natural resources for exploitation by our children in the future without affecting current production.

Recycling contributes to creation of jobs

To add to the benefits it brings to the environment; recycling opens up job opportunities. Recycling means many recycling plants will be set up, thus, leading to a long chain of collection and delivery. All these activities are performed by humans, so this will trigger an explosion of opportunities.

Reduces energy consumption

A lot of energy is used to process raw materials in the course of manufacture. Recycling plays a big role in reducing energy consumption, which is vital for large-scale production, for instance, mining and refining. Recycling also renders the whole process of production less expensive, which is a great victory for manufacturers.

![]()